- Contact Us

- 1-888-948-9378

SGE Environmental GC Columns

Trajan Scientific and Medical is a vertically integrated manufacturer of gas chromatography columns, with all aspects of column manufacture controlled at one site.

Click here for Guidelines for Choosing GC Columns.The Suite for Environmental GC Analysis

SGE GC Columns have a history of being effective columns for the separation of environmental analytes.

Since Trajan Scientific and Medical acquired the SGE business, significant focus has been invested in improving the manufacturing process and phase synthesis to ensure the performance, consistency and quality of the GC column meets the needs of the analysis in the laboratory.

The range of GC columns presented for environmental analysis now delivers improved performance, selectivity and a guarantee on delivery, making SGE GC columns by Trajan a key product for the Environmental laboratory.

End-to-End Capillary Column Manufacture

With the complete technical ability to produce GC columns from beginning to end, including the special requirements of producing fused silica capillary tubing, Trajan controls fabrication process precisely to produce the finest quality GC columns available.

The individual technology processes Trajan employs in GC column manufacture are:

- Drawing of the precision fused silica capillary tubing.

- Developing and synthesizing specialty polymer stationary phases.

- Performing the specialized chemical treatment of the fused silica surface so it is inert and compatible for the

- Cross-linked stationary phase.

- Coating and cross-linking the polymer stationary phase.

- Quality testing of every completed GC column to rigorous standards.

Fused Silica

The process of producing fused silica tubing is carried out on a series of sophisticated drawing towers with fine control of conditions and feedback loops to automatically make adjustments to the conditions. This ensures superb dimensional control and strength which is verified through stress proof testing of all material. By producing the fused silica in-house, Trajan has complete control of this important aspect of producing the highest quality GC columns.

The fused silica used by Trajan is very high purity devoid of impurities such as metal oxides found in conventional glasses. SGE GC columns operate comfortably to 400 °C (dependent on the phase selected).

Stationary Phase Polymer

Trajan has designed its phase synthesis so that most GC columns may be washed with solvent to remove any contamination. When a capillary column’s performance has deteriorated from extended use or contamination, performance can often be restored though washing with a suitable solvent.

Targeted Performance Testing

Test criteria are selected based on the applications that different capillary column types are targeted for, to ensure the capillary column meets the standards for that analysis. General purpose capillary columns are tested to ensure they meet inertness standards for difficult to chromatograph compounds, and run at conditions and levels designed to highlight variations in capillary column performance.

For example, Trajan’s non-polar phase BPX5 is tested using active probes such as n-decylamine and 2,4-dinitrophenol chromatographed at low concentrations (1-2 ng on capillary column for 0.25 μm film thickness) and with sufficient retained time on the run to induce tailing on all but the most highly inert GC columns.

Retention Time and Consistency

Because Trajan controls the GC column fabrication process from beginning to end, remarkably consistent retention characteristics can be achieved from column to column. When a method is established on an SGE GC column, the same separation can be expected column after column.

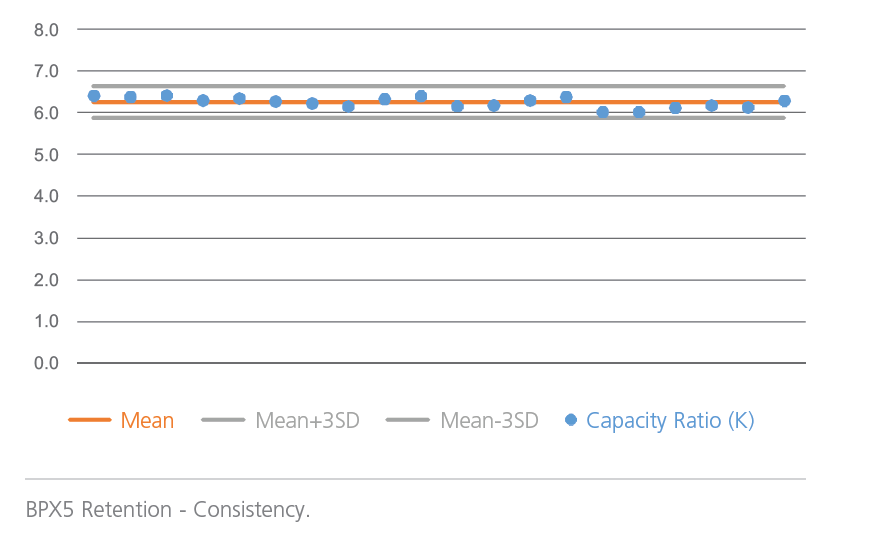

Enhanced retention time consistency achieved through manufacturing improvements is demonstrated here for capacity ratio (K) measured on 20 BPX5 columns showing very high congruence.

Selectivity

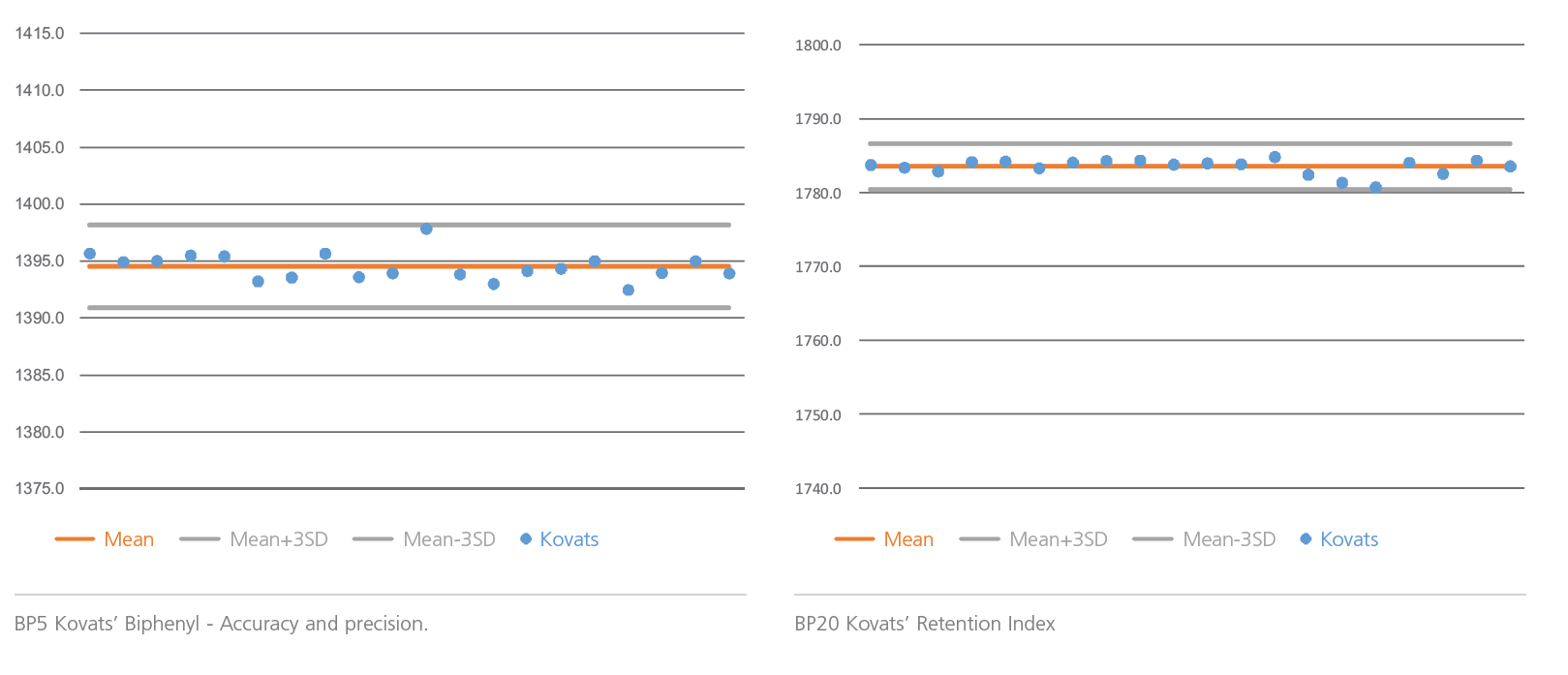

SGE GC columns deliver accurate retention indices with high precision to ensuring confidence in peak identification for non-polar and polar stationary phase columns.

Retention index repeatability is shown here for 20 BP5 columns and for 20 BP20 columns.

Thermal Stability

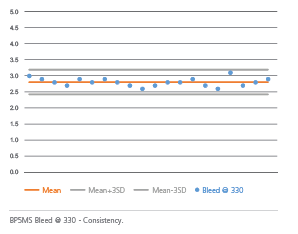

SGE GC columns are monitored for bleed performance with rigorous standards. Bleed is measured and specified in terms of detector signal and calibrated to “nanograms of siloxane per second” eluted from the GC columns. The test is performed at the maximum operating temperature for the GC column. Picoamp signal is highly dependent on the detector and conditions used and is not an absolute measure. Bleed measurements are carried out using FID to ensure the best performance possible.

Results from BP5MS column testing (20 columns) highlight the low bleed expected of SGE GC columns.

GC Columns for Environmental Analysis

| Phase | Stationary Phase | Overview | Phase Structure | Application Notes |

|---|---|---|---|---|

| BP1 | 100% Dimethyl Polysiloxane |

|

|

Suitable for all routine analysis. |

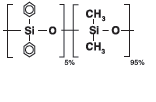

| BP5 | 5% Phenyl / 95% Dimethyl Polysiloxane |

|

|

Suitable for all routine analysis. |

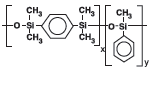

| BPX5 | 5% Phenyl Polysilphenylene-siloxane |

|

|

Excellent for all routine high-temperature applications. |

| BP5MS | 5% Phenyl Polysilphenylene-siloxane |

|

|

Suitable for all routine GC-MS analysis. |

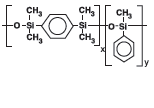

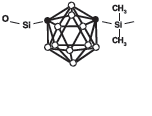

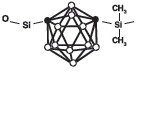

| HT5 | 5% Phenyl Polycarborane siloxane |

|

|

|

| HT8 | 8% Phenyl Polycarborane siloxane |

|

|

|

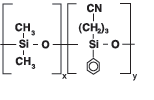

| BP624 | Cyanopropylphenyl Polysiloxane |

|

|

|

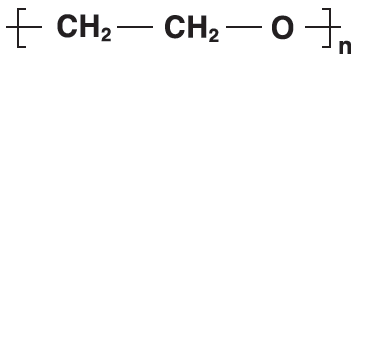

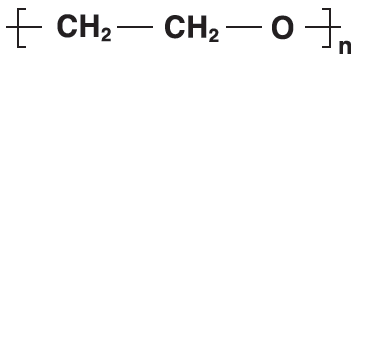

| BP20 | Polyethylene Glycol |

|

|

Industry standard wax column for polar compounds analysis. |

| SolGel- WAX | Polyethylene Glycol (PEG) in a Sol-Gel matrix |

|

|

Very robust high-temperature column for polar compounds analysis. |

Click here for Guidelines for Choosing GC Columns.